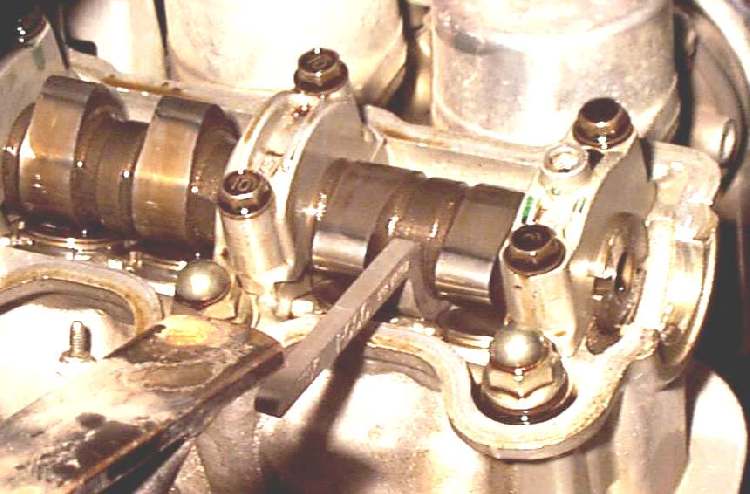

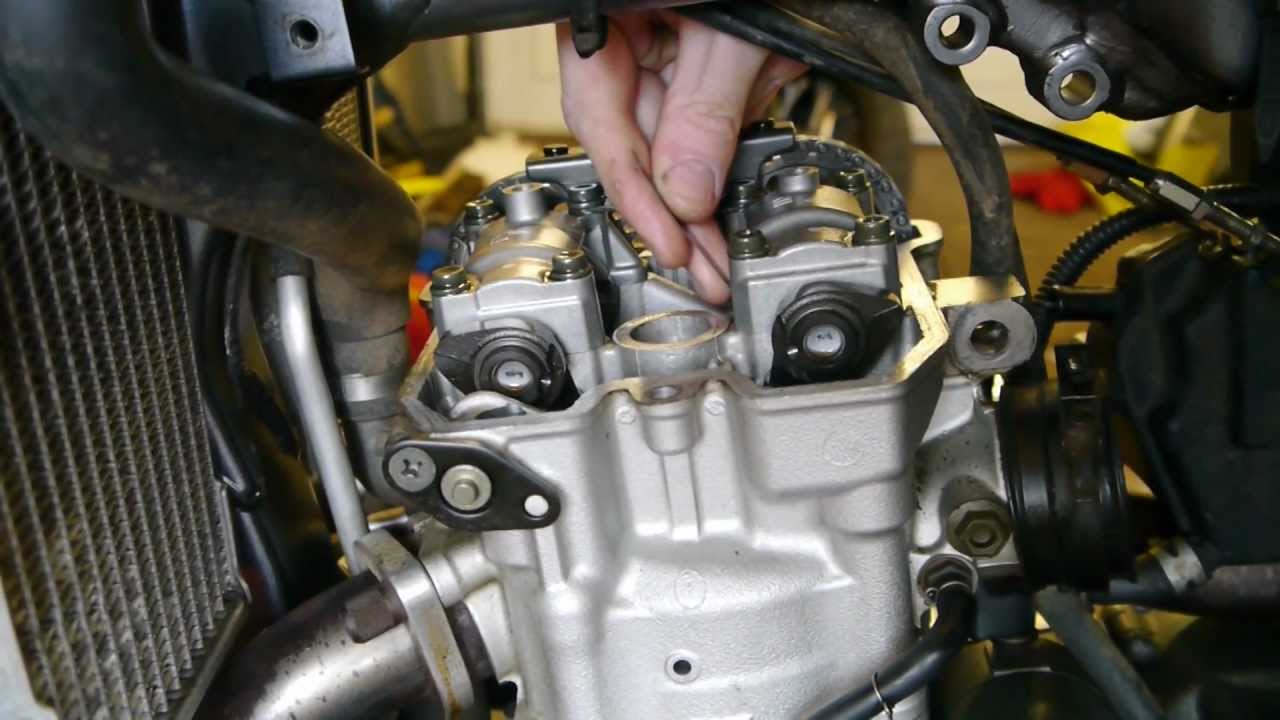

When it comes to valve settings, I use what is specified for the cam, not the head. So, I think the noise is still there, it just doesn't penetrate the iron head and escape. I've even got a set of 3134's in there and it's still quieter than any other Triumph. That bike was quiet, in comparison, but nothing beats my iron head for quiet running. It made degreeing the cams rather difficult. Weird, the ramps were loooong, about 1/4 of the base circle. However, on one bike I did use a set of new T110 cams they had ramps built in for quiet running. I don't think you're going to get around that. It makes a huge difference in the clatter. I keep matched sets around the place, especially unit ones to replace the narrow pre unit unit ones. I've never seen new camwheels available, but of course I've never been looking either. But 16 seconds in the 1/4 mile? I would have thought that 14 sec is within reach. It does not seem overly noisy at startup, and I can still hear some ticking when it is at operating temperature, which I interpret as a good thing to hear.Ĭool bike. If valve no 8 is fully open then 9 - 8 1 Now set valve clearance of no 1 to. Turn crankshaft in direction of rotation until any valve is fully open. Setting valve clearances on your Perkins 4 cylinder motor is very staightforward. Once I got my bike running, I went with the. Setting valve tappet (Cam followers) clearances on your Massey Ferguson 4 cylinder motor. Then there was a TriCor Service Bulletin dated 11/29/63 (Service Notes - Useful information - First Delivery of 1964 Models) that said,"For the T120R and TR6R Models, we suggest. 004" exhaust clearance (cold) for the 6T, TR6, and T120. I believe this is true with most engines that have manually set valve clearances. Because of thermal expansion, the exhaust valve needs to have a greater intial clearance. The exhaust valve, on the other hand is perhaps the hottest part in the engine. The intake valve continually has a relatively cool, fresh charge of air and fuel coming past it. When you say that this is the other way around for most engines, I'd say, yes, you are confused about that. It sounds like you are asking why the intake valve is set to less initial clearance than the exhaust. Use a 4-mm Allen wrench to tighten the fairing's bolts.What I do not get is why the other way around? why the intake have that measurement the logic of the motors is not the other way? or Am I confused? Reattach the seat and reinstall any fairings removed earlier. Reinstall the gas tank onto the motorcycle and reconnect the fuel line to the carburetor. Screw the tachometer cable into the cylinder head cover and tighten it by hand. Reinstall the right crankcase cover and tighten its bolts with a four-mm Allen wrench. Reinstall the cylinder head cover onto the motor, and tighten its bolts with a 10-mm socket. Repeat this step to check and adjust the remaining intake valve clearances. Measure the valves' clearance with a feeler gauge, and replace the shims as needed. Rotate the crankshaft 180-degrees counterclockwise with a wrench so that the exhaust camshaft's cams are away from the exhaust valve's shims on the left side of the motor. Measure the valves' clearance with a feeler gauge and replace the shims as needed. Rotate the crankshaft 180-degrees counterclockwise with a wrench so that the intake camshaft's cams are away from the intake valve's shims on the right side of the motor. Skip this step if the clearance of the first two exhaust valves are within 0.001 to 0.003 of an inch. Coat the top and bottom of the new shim with 10W40 motor oil, then slide the shim into place over the tappet. Push the exhaust valve's tappet away from the cam, then pull the shim off of the valve with forceps. Suzuki specifies a clearance range of 0.001 to 0.003 of an inch of clearance between the cam and the top of the tappet.Īdjust the exhaust valve's clearance by replacing the existing shim with a new shim that is slightly larger or smaller than the original shim, according to the measurements taken in the previous step.

Measure the clearance between right exhaust cams and their tappets with a feeler gauge. Stop when the exhaust camshaft's round-tipped cams on the right side of the motor are pointed at a 90-degree angle away from the top of the cylinder head.

Rotate the crankshaft counterclockwise with a wrench to turn the camshafts. The GS motors are equipped with two camshafts the camshaft at the rear of the cylinder head controls the intake valves the forward camshaft controls the exhaust valves. Lift the cylinder head cover off of the motor to access the valve tappets and camshafts. Unscrew the cylinder head's bolts with a 10-mm socket. Unscrew the tachometer cable from the motor's cylinder head cover, if present, using a pair of rubber-jawed pliers.

0 kommentar(er)

0 kommentar(er)